6100 Series Coriolis Mass Flow Controller and Meter

- Full Scale Flow Range: 40g/h-300kg/h for liquids

0.53slm-4000slm for gases(N2) - High pressure rating-up to 3000 psi(g)/207 bar(g)

- Higher-precision measurement and control

- Multiple communication options

- Multi-parameter multi-function output

- High-definition touch screen

Description of 6100 Series Coriolis Mass Flow Controller and Meter

Mass flow meters based on the Coriolis principle are highly appreciated for their accuracy and independence from the properties of the fluid.

The Biosflow 6100 series is a precise mass flow meter/controller for measuring gas and liquid flows up to 207 bar(a) and is virtually insensitive to pressure and temperature variations.

The Biosflow 6100 series Coriolis mass flow meter/controller can measure flow rates ranging from 40g/h to 300kg/h. It contains a uniquely shaped single-loop sensor tube that forms part of an oscillating system. As the fluid flows through the tube, the Coriolis force causes a variable phase shift that is detected by the sensor and fed back to a high-speed microprocessor PC board for processing, which produces an output signal that is strictly proportional to the mass flow rate.

The Biosflow 6100 series is a true mass flow meter/controller that measures mass flow, regardless of the nature of the gas or liquid. A high accuracy proportional control valve and a flexible readout are used within the system to measure and control gas and liquid flows.

All instruments in the Biosflo 6100 series offer unmatched accuracy and zero stability in demanding low-flow applications. They can simultaneously measure multi-parameters such as mass or volume flow rate as well as density and temperature of the output fluid.

Biosflows 6100 Series Coriolis Mass Flow Controller and Meter

| MODEL NAME | 6110/11 | 6120/21 | 6130/31 |

|---|---|---|---|

| FEATURE | |||

| Full Scale Flow Range | Liquids:40g/h-5kg/h Gases:0.53slm-66.6slm (N2) | Liquids:3kg/h-100kg/h Gases:40slm-1333slm (N2) | Liquids:10kg/h-300kg/h Gases:133slm-4000slm (N2) |

| Mass Flow Accuracy | Liquids:±0.2%/±0.25%/±0.6% of reading Gases:±0.5%/±0.6%/±1% of reading |

||

| Turndown Ratio | 6100 Series better than75:1/ (optional:100:1)\ 6101 Series better than 100:1/ (optional:200:1) | ||

| Repeatability | ±0.05% of reading or ±0.025% of full scale, whichever is greater | ||

| Response Time | 40g/h-5kg/h<100 ms | 3kg/h-100kg/h<150 ms | 10kg/h-300kg/h<200 ms |

| Control Response Time | 40g/h-5kg/h<200 ms | 3kg/h-100kg/h<250 ms | 10kg/h-300kg/h<300 ms |

| Temperature Sensitivity | Mass flow zero shift: ±0.01% of full scale per °C from tare temperature Mass flow span shift: ±0.005% of reading per °C from 25°C |

||

| Zero Stability | ±0.05% of full scale (included in mass flow accuracy) | ||

| Density Range | 0–500 cP (Consult Grylls for higher viscosity options) | ||

| Density Accuracy | <±5 kg/m3 | ||

| Temperature Accuracy | ±0.5℃ | ||

| OPERATING CONDITIONS | |||

| Working Temperature Range | 0-70 ℃ | ||

| Minimum Pressure Difference (controller, fluid water) | 14.5psi(d)/1bar(d) | Min.: 14.5 psi(d)/1bar(d) | Min.:60psi(d)/4bar(d) |

| Maximum Pressure Difference (Controller) | 72.5 psi(d)/5 bar(d) | ||

| Maximum Working Pressure | 435 psi(g)/30bar(g)\Option:1450psi(g)/100bar(g) Maximum Working Pressure \Max:3000psi(g)/207bar(g) | ||

| Leak Rate | Outboard 1 x 10-9 atm. cc/sec., helium | ||

| MECHANICAL | |||

| Valve Type | 6100 Series Normally Closed/Optional:Normally Open \ 6111 Series NO Valve | ||

| Wetted Material | 316L Stainless Steel\Viton seals\ EPDM seals\Silicone seals\FFKM seals | ||

| Installation Direction | May be mounted in any position | ||

| Weight | About 6100:1.0kg / 6111:0.75kg | About 6120:1.2kg / 6121:0.85kg | About 6130:2.0kg / 6131:1.5kg |

| ELECTRICAL SPECIFICATIONS AND INTERFACE | |||

| Electrical Interface | 9-Pin Male Sub D-Type /15-Pin Male Sub D-Type (optional)/RJ11/USB -C | ||

| Analog Input Signal | 0-5 Vdc / 1-5 Vdc / 0-10 Vdc / 4-20 mA | ||

| Analog Output Signal | 0-5 Vdc / 1-5 Vdc / 0-10 Vdc / 4-20 mA | ||

| Digital communication | RS-232 Serial / RS-485 Serial / Modbus RTU Option: PROFIBUS / EtherNet/IP / DeviceNet /Modbus TCP/IP / EtherCAT / PROFIBUS-DP |

||

| Power Consumption | About 12.0w 24Vdc @500 mA | About 18.0w 24Vdc @750 mA | About 24.0w 24Vdc @1000 mA |

| Touch Screen Display | Display Mass Flow, Density, Temperature, Cumulative flow and Flow set point | ||

| Operational | 6100/11 Series | 6120/21 Series | 6130/31 Series |

| Full Scale Range | 0-40g/h | 3kg/h-30kg/h | 10 kg/h-100kg/h |

| 40g/h-500g/h | 10kg/h-50kg/h | 30kg/h-300kg/h | |

| 100g/h-1000g/h | 20kg/h-100kg/h | For a larger flow range, consult Biosflows | |

| 500g/h-2000g/h | / | / | |

| 1000g/h-5000g/h | / | / | |

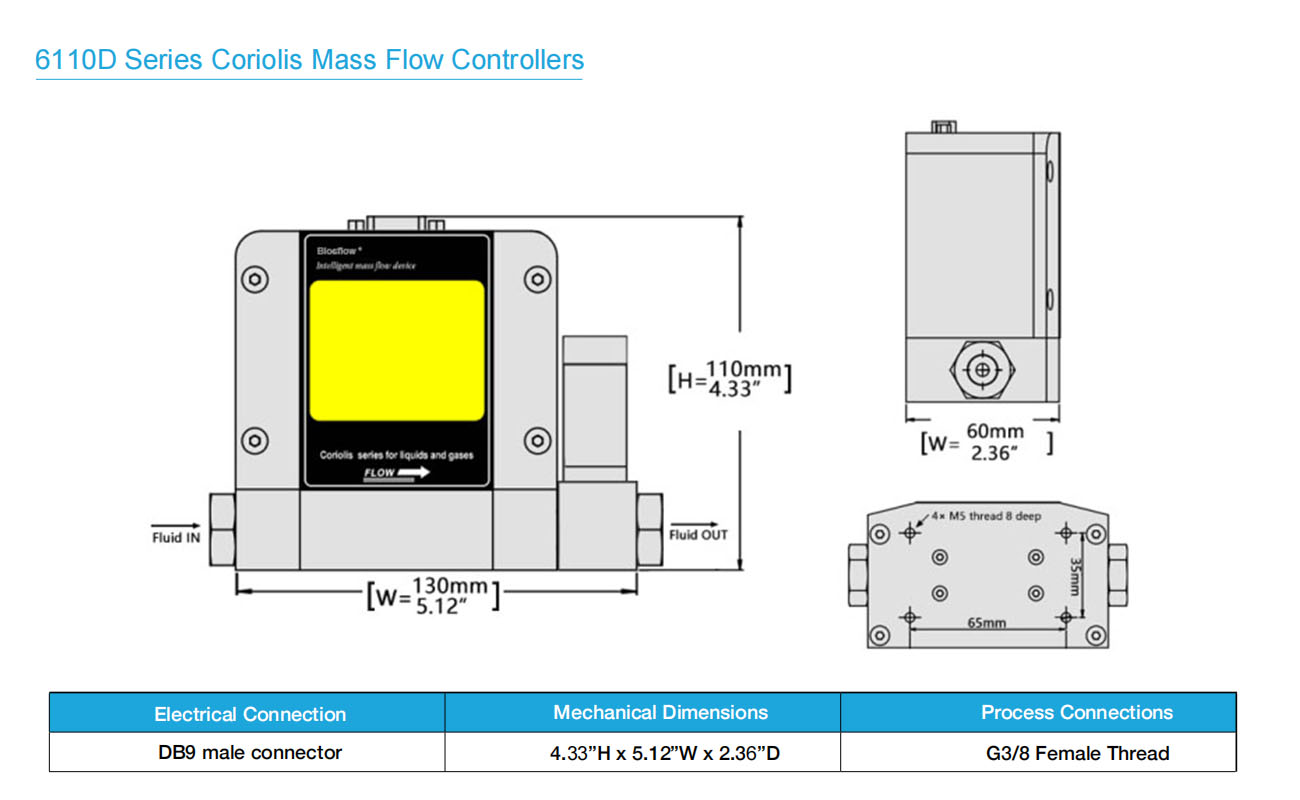

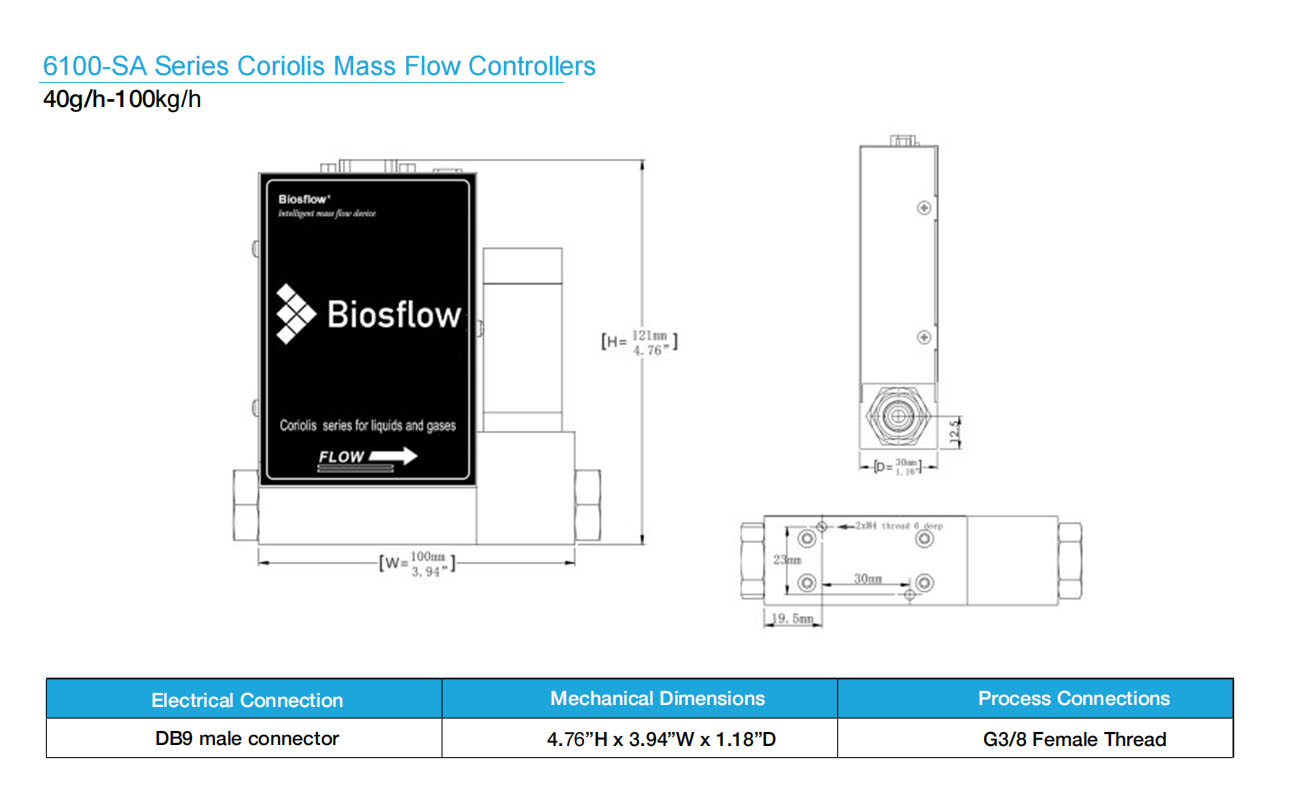

6100 Series Coriolis Mass Flow Controller and Meter Size

Features of 6100 Series Coriolis Mass Flow Controller and Meter

1. Higher-precision measurement and control

0.2% reading for liquids

0.5% reading for gases

Turndown ratio better than 75 : 1

(optional:100:1/200:1)

2. Wider flow range

Min:40 g/h for liquids

Max:300 kg/h for liquids

Min:0.53 SLM for gases (N2)*

Max:4000 SLM for gases (N2)*

3. Multiple communication options

Traditional 0-5 Vdc and 4-20mA analog options

as well as RS232/RS485 digital communications

are available(Modbus RTU protocol).

4. Multi-parameter multi-function output

Direct mass flow measurement

Independent of fluid properties

Additional density and temperature outputs

5. Optional

1)High pressure rating – up to

3000 psi (g)/207 bar (g)

2)Water/dust-resistant:ip65

6. High-definition touch screen

Display of flow rate, total and measuring

unit. Defining a set point.

6100/6101D series only)

7.Biosflow UCS Software

Efficient device management with the

free software:

View flow rate & cumulative flow

Change set pointsChange set

Change set communication address

Visualization of measured data communication mode

Datalogging

Change digital / analog

communication mode

Multiple 6100 devices can be controlled

at the same time

Application of 6100 Series Coriolis Mass Flow Controller and Meter

2) Photovoltaic industry

3) Fuel cell

4) Vacuum industry

6) Heat treatment

7) Surface treatment

8) CHEMICAL. PLASTICS, METAL

AND GLASS INDUSTRY

10) Food, Beverage and Pharma

11) Automobile electronics

12) Bioprocessing & Bioreactors