EDC-510A/B Massflow Controller and Meters

- Full Scale Flow Range: 3sccm-10sccm

- Maximum Pressure Rating: 500Psi / 30Bar

- Repeatability: ±0.2% F.S

- Control Range: 1~100% F.S

- Response Time: <1s

- Operating Temperature:0~50℃

- Digital Communication:RS-485/DeviceNet

- Analog Communication:0~5 V / 4~20mA

Description of EDC-510A/B Massflow Controller and Metes

In addition to using the previous generation of advanced “temperature difference automatic balance technology” sensors, the EDC-500 series also combines ultra-high stability and accuracy measurement sensors with fast, precise control valves and powerful electronic components. Together they achieve precise gas process control. High-integrity ultra-high-purity all-metal flow path and long-term effective sealing performance can ensure the purity of the process. EDC-500 series is very suitable for semiconductor industry and high-purity gas occasions.

Biosflows EDC-510A/B Massflow Controller and Metes Technical Parameters

| Performance | |

|---|---|

| Flow Accuracy | ±0.8% R.D and±0.2% F.S |

| Repeatability | ±0.2% F.S |

| Control Range | 1~100% F.S |

| Response Time | <1s |

| Temperature Coefficient | Zero: <0.05% of F.S./℃. Span: <0.1% of S.P. /℃ |

| Pressure Coefficient | 0.2% of S.P. / Bar |

| Operating Temperature | 0~50℃ |

| Leak Rate | 1x10-11 atm. cc/sec He |

| Preheat Time | 5 min accuracy to ±2% F.S (30 min to achieve the best accuracy) |

| Electrical Parameters | |

| Power Supply | +15~24 V dc |

| Maximum Power Consumption | 10W (MFC); 3W (MFM) |

| Digital Communication | RS-485 / DeviceNet |

| Analog Communication | 0~5 V / 4~20mA |

| Electrical Interface | 9-pin D-Connector (male) / DeviceNet Connector |

| Mechanical Parameters | |

| Valve Type | Normally closed (MFM meaningless) |

| Substrate Material | 316L stainless steel |

| Sealing Material | Rubber seal/Metal seal |

| Process connections | VCR / IGS Fittings |

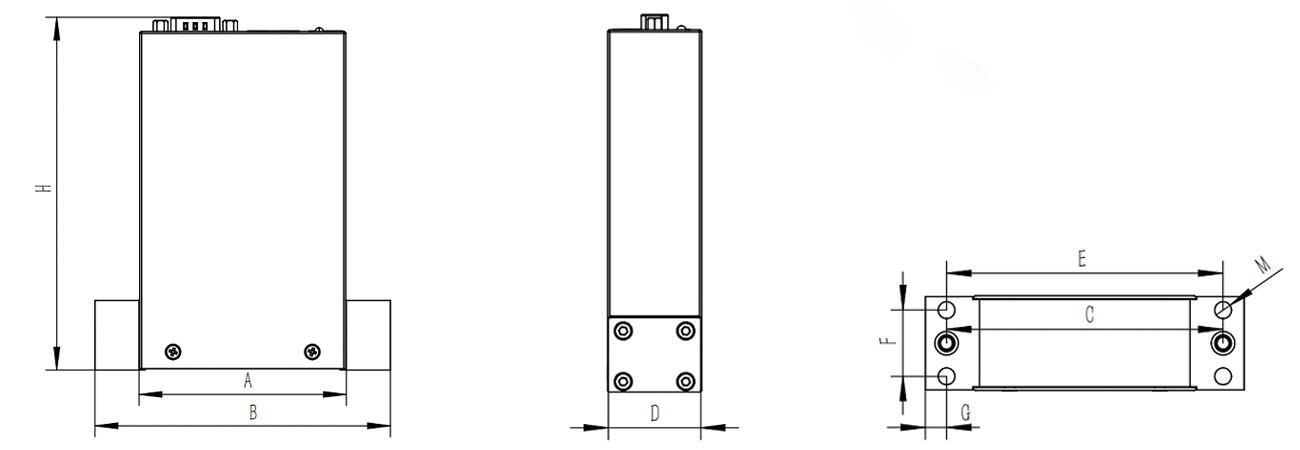

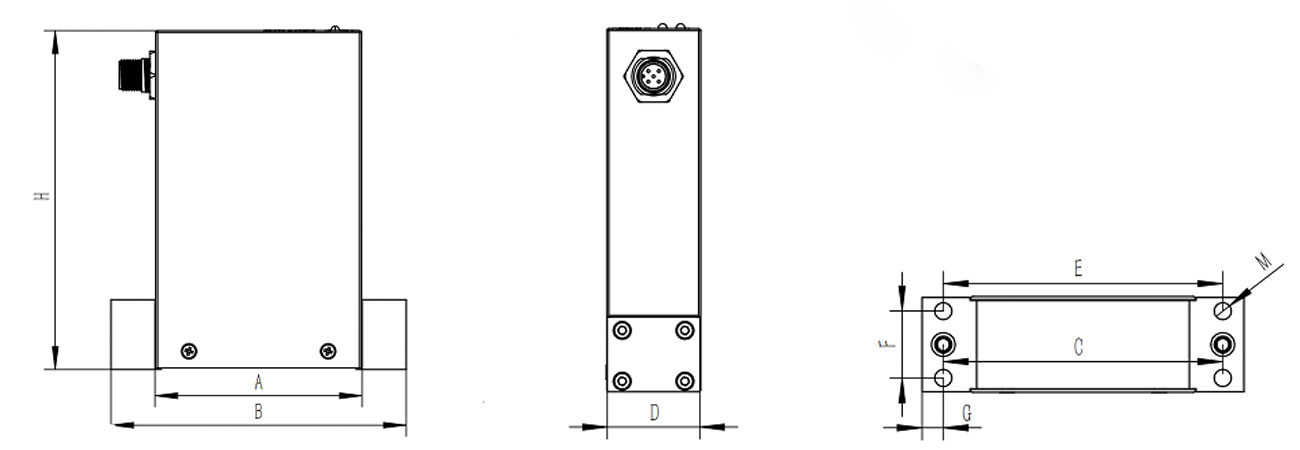

EDC-510A/B Massflow Controller and Metes Size and Weight

| Model | A | B | C | D | H | E | F | G | M | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| EDC-510A | 74 | 106 | 92 | 31 | 125 | 92 | 22 | 7 | 5.8 | 0.6 |

| EDC-520A | 74 | 106 | 92 | 31 | 125 | 92 | 22 | 7 | 5.8 | 0.6 |

| EDC-510B | 74 | 106 | 92 | 31 | 120 | 92 | 22 | 7 | 5.8 | 0.6 |

| EDC-520B | 74 | 106 | 92 | 31 | 120 | 92 | 22 | 7 | 5.8 | 0.6 |

Features of EDC-500 Massflow Controller and Metes

All Metal Sealed Gas Flow Path

High-integrity ultra-high-purity all-metal flow path with choice of 4µ or 10µ inch Ra surface treatment, long-term effective sealing performance, and corrosion-resistant sensors improve the reproducibility of measurement results at high temperatures to to ensure purity of process. Welcome to inquiry in Biosflow.

High Reliability and Performance

High-performance components are tested seven times consecutively in accordance with semiconductor industry standards to ensure their reliability, which is superior to semiconductor industry standard levels in reliability, ensuring reproducible measurement results and highly stable performance over a long period of use.

New Generation Sensor Design

Innovative sensor design, small influence of temperature and pressure changes, accurate temperature and pressure correction, high linearity can provide excellent signal-to-noise ratio performance to improve measurement and control accuracy under low set-point conditions Long-term zero point stability.

Multi-gas and span adjustment functions

Choose one device platform to meet the needs of different gases and flow ranges, store and pre-set multiple gas calibration information, users only need one device to easily switch between different gases and ranges and reduce inventory, through software or PLC can be implemented without disconnecting the instrumentation from the system.

Aplication of EDC-500 Massflow Controller and Metes

Epitaxial Process System

The epitaxial process refers to the process of growing a fully aligned single crystal layer on a substrate. In the manufacture of integrated circuits, the commonly used epitaxy method is vapor phase epitaxy. During the epitaxy process, the gas flow into the reaction chamber needs to be precisely controlled. MFC can be equipped on the gas supply line. By adjusting the control parameters of MFC (such as current or pressure), precise control of gas flow can be achieved to ensure stable and accurate gas flow required in the epitaxy process.

Photovoltaic Industry

A certain amount of gas needs to be supplied during the preparation of solar cells, such as precursor gas and protective gas used to prepare thin films. MFC can be used to control the flow of these gases to ensure the stability and repeatability of the solar cell fabrication process. Flow devices are used in the application layer of crystalline silicon wafers for conventional silicon-based solar cells, as well as in the fabrication of thin layers on flexible substrates as second-generation amorphous silicon-based thin-film solar cell components.

Vapor Deposition System

Vapor deposition is a commonly used thin film preparation technology. The gas precursor is sent into the reaction chamber, and the gas precursor is deposited on the surface of the substrate to form a thin film through a chemical reaction or physical process. MFC can accurately control the gas flow during the vapor deposition process according to the preset gas flow to ensure the stability of gas concentration and flow in the reaction chamber. Biosflow is the professional manufacturer of EDC-500 series of Massflow Controller.