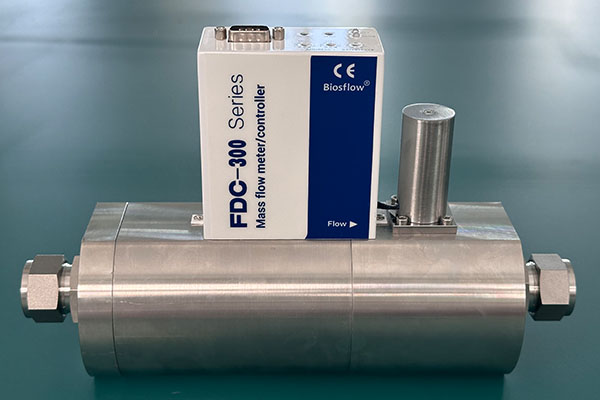

MFC mass flow controller for gas supply and control

A variety of gases are required in the semiconductor manufacturing process. Such as nitrogen, hydrogen, argon, etc. So mfc mass flow controller can accurately measure and control the flow of different gases. To ensuring a stable supply of gas and accurate control of flow in the semiconductor manufacturing process.

![]()

The role of mfc mass flow controller in cleaning and drying

In the semiconductor manufacturing process. Because wafers and equipment need to be cleaned and dried. In order to remove impurities and moisture. So Gas mass flow meters can control the gas flow. During the cleaning and drying process. To ensure the cleaning and drying effect.

What role does mfc mass flow controller play in gas mixing and purification?

In some specific semiconductor processes, multiple gases need to be mixed in a certain proportion. Therefore, Gas digital mass flow controller can monitor and adjust the flow of different gases in real-time. According to the set ratio requirements. In order to ensure accurate control of the ratio of the mixed gas. In addition, mfc mass flow controller can also detect the content of impurities and pollutants in the gas for gas purification.

[one_half padding=”0 10px 0 0″]

[/one_half][one_half_last padding=”0 10px 0 0″]

[/one_half][one_half_last padding=”0 10px 0 0″] [/one_half_last]

[/one_half_last]

The safety role of MFC in gas leak detection and protection

Most importantly, in the semiconductor manufacturing process. Because any gas leak may cause contamination and failure in the manufacturing process, so the mfc flow controller monitors the changes in gas flow in real time, this is very important to the end user. Because when the gas flow exceeds the set threshold or changes suddenly. An alarm can be issued and corresponding measures can be taken for leak detection and repair. To ensure the stability and quality of the semiconductor manufacturing process. So choosing a high-quality MFC manufacturer is very important.

Importance of mfc mass flow controller in Wafer Manufacturing Process

Digital flow controllers are used widely in the Chemical Vapor Deposition (CVD) process. As we all know, CVD is a technology that deposits thin films on the surface of wafers through chemical reactions. So precise control of the flow rate of reaction gases is crucial to the quality and uniformity of the film. Thus mfc mass flow controller can adjust the gas flow rate with extremely high precision. To ensure that the reaction is carried out under stable conditions. For example, when depositing insulating or conductive layers. So digital mass flow controller can precisely control gas flow. So that it can achieve uniform film thickness. And avoid circuit performance problems caused by uneven thickness.

[one_half padding=”0 10px 0 0″] [/one_half][one_half_last padding=”0 10px 0 0″]

[/one_half][one_half_last padding=”0 10px 0 0″] [/one_half_last]

[/one_half_last]

MFC mass flow controller is indispensable in the PVD process.

PVD is a technology that deposits materials on the surface of the wafer by physical methods. Such as sputtering coating. In this process, we need to precisely control the flow rate of sputtering gas. In order to ensure the quality and uniformity of the coating. So gas flow controller can monitor and adjust the gas flow in real time. So that to ensures the stability of the sputtering process, thereby obtaining high-quality coatings.

MASS Flow Controller plays an important role in the etching process

Etching is the removal of material on the surface of the wafer. It through chemical reactions or physical methods to form a specific circuit pattern. So precise control of the flow rate of etching gas can control the rate and depth of etching. So to ensure the accuracy and consistency of etching. Thus mfc mass flow controller can quickly respond to changes in process parameters. And adjust the gas flow in time. To ensure the smooth progress of the etching process.

How to find the best MFC Manufacturer in the semiconductor industry?

As we all know, there are many mass flow controller manufacturer in the world. However many mass flow controller company is not manufacturer. Because they just put their own brand on other manufacturers’ MFCs. So they don’t have their factory. Thus, they don’t understand the product, and their price is not competitive. Most importantly, their after-sales service is not good either. Because they only sell MFC for profit. But Biosflow (Zhengzhou) Electronic Technology Co., Ltd. Is a real mfc mass flow controller manufacturer in China. They not only have their own production team but also their own R&D team. In addition, they also have their own sales team and a strong after-sales service team. So please feel free to choose them, Biosflow will provide you with the best quality products and the lowest prices.

In short, the application of mfc mass flow controller in the semiconductor manufacturing industry runs through the entire production process. With its high precision, high reliability, and fast response. Not only it provide key flow control solutions for semiconductor manufacturing, But also ensures the quality and performance of semiconductor products. With the continuous development of semiconductor technology. The role of mfc mass flow controller will become more prominent and make greater contributions. In order to promote the progress of the semiconductor industry.